High Surface Area, High Energy, Un-Oxidized, Aluminum NanoFlakes for Explosives and Solid Propellants

Utilizing its unique manufacturing process for creating un-passivated, ultra-high surface area, nano-aluminum, SigMaterials is able to produce high performance nano-composites with reduced agglomeration for higher burn efficiencies.

FIGURE: 100-500nm Un-Oxidized Aluminum and Polymer Nano Composite

FIGURE: 100-500nm Un-Oxidized Aluminum and Polymer Nano Composite

Un-Reacted Aluminum = Super-High Reactivity

The process begins by creating a multi-layer laminate consisting of thousands of alternating layers of a polymer and aluminum. This nanolaminate is produced entirely under vacuum; so, unlike conventional aluminum nanopowders, which are produced in atmosphere, the aluminum layers that make up the nano-laminate have not had a chance to react with atmospheric oxygen; adjoining polymer layers create a barrier to oxygen when exposed to air. This process results in the production of a highly reactive, nano-thick, aluminum layer that is further processed (crushed) to produce a fine powder consisting of nanoflake composites with ultra-high surface area. Applications include solid rocket fuel propellants and high-energy explosives.

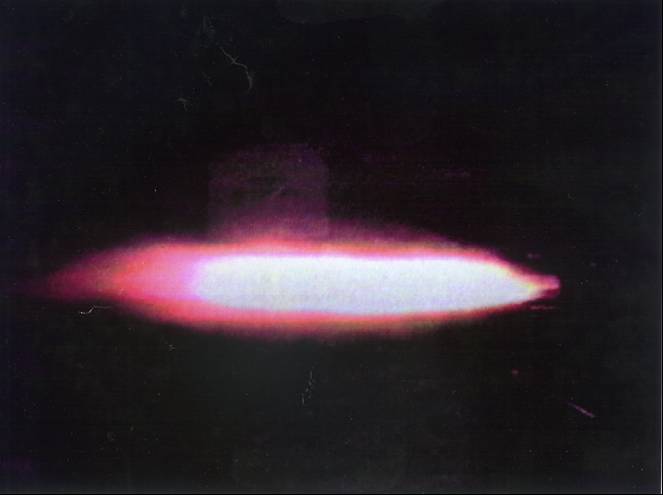

Key Benefits for High-Energy Explosives FIGURE: Exhaust Plume of a Nano-Composite Fuel Hybrid Rocket

FIGURE: Exhaust Plume of a Nano-Composite Fuel Hybrid Rocket

- Ultra high metal surface area in a single nano-composite particle

- Aluminum metal is pure and unoxidized

- Particles have electrostatic sensitivity equal to that of conventional aluminum powder

- Other metals and alloys are possible

- A higher energy integrated fuel system can be produced with a fluorine containing polymer

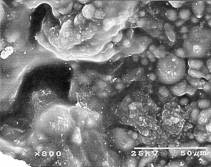

FIGURE: Combustion Surface of Partially Burned HTPB + Al Fuel Showing Al Agglomeration

FIGURE: Combustion Surface of Partially Burned HTPB + Al Fuel Showing Al Agglomeration

Key Benefits for Solid Rocket Fuel Propellants

- Improved burn efficiency

- No detectable agglomeration

- Superior mechanical strength when blended with HTPB fuel grain

- Reduced slag formation

- Complete aluminum oxidation

- Very low signature (low smoke generation) due to small size of the oxidized aluminum nanoflakes

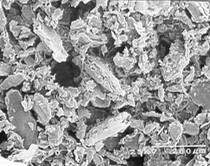

FIGURE: Combustion Surface of Nano-Composite Fuel Showing NO Agglomeration

FIGURE: Combustion Surface of Nano-Composite Fuel Showing NO Agglomeration